Seeing the Invisible with Thermal Imaging Technology

The COVID-19 pandemic has completely reshaped the way the world works – but it is far from being the last global pandemic we may face in our lifetime. Scientists have already predicted a 47-57% chance of a future pandemic threat occurring in the next 25 years, meaning another potentially overwhelming shake up of global systems and processes. As it is, the Delta variant of the COVID-19 virus continues to affect communities worldwide, and new variants might still emerge with unknown complications and health risks.

In light of these current and future threats, businesses must take a proactive role in ensuring the safety of their workers and employees as well as the security of their logistics. Many enterprises have adopted Smart Monitoring technology to help adapt to the changing uncertainties of the pandemic. Konica Minolta’s Smart Monitoring solutions enable remote monitoring built upon image recognition and Artificial Intelligence (AI). One application of this intelligent video platform that is already making a difference in workplaces worldwide is Thermal Imaging technology.

Protecting workers on the ground

Many workplaces have adopted new health and safety protocols to ensure safe distancing guidelines are adhered to. One such measure is regular body temperature checks, which can preemptively ensure that potentially unwell individuals do not enter the premises or interact with other personnel. Thermal Imaging technology enables contactless mass screening of elevated body temperatures, allowing for accurate and efficient detection of potential health risks. When integrated with an IoT network, these assessments can be instantly connected to human resource databases to streamline the updating of employees’ health records and facilitate contact tracing protocol.

With an automated IoT network driving detailed and accurate records keeping, businesses can devote less resources to keep up with evolving safety measures. As more businesses move towards a Work-From-Home model in order to protect employees, Thermal Imaging technology can play a part in the Hybrid workplace as well. Thermal Imaging, along with optional face recognition features allows authorised personnel to monitor warehouse or workplace operations remotely along with attendance or visitor management. Personnel that were previously required to be present on-site can now work remotely without sacrificing the security of their logistics, resulting in enhanced safety protocols for workers with no loss in efficiency.

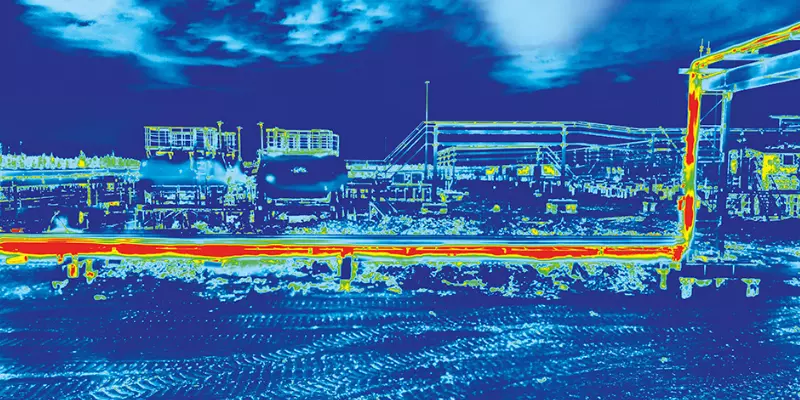

Process Temperature Control in Manufacturing

The applications using Thermal Imaging technology for contactless temperature monitoring in manufacturing can vary from chemical compounds processing, food processing, metal plating process, to glass blow molding.

Thermal Imaging technology can monitor temperature range between -40° to 550°C with 0.1°C resolution, to ensure your logistics are kept at the precise temperature required for optimal performance and results.

The monitored results can be integrated into automated manufacturing equipment using commonly available industrial interface standards like MODBUS (RS485). A full automated temperature control or in-situ quality assurance can be built-in as part of the manufacturing process, helping you streamline temperature control functions with the rest of your workflow for better efficiency.

Ensuring smooth transport and delivery of logistics

Thermal Imaging technology can also be utilised in logistics management particularly when maintaining cold storage capabilities is crucial. By tracking the temperature range in cold storage vehicles and facilities with IoT, even the slightest change in temperature can trigger immediate notifications to begin rectification and recalibration.

In temperature sensitive biomedical products and fresh food delivery sectors that depend heavily on maintaining specific acceptable temperature ranges during the end-to-end delivery process, smart monitoring technology could help with cold chain handling compliance.

Re-envision a smart and secure workplace with Konica Minolta

Konica Minolta’s Smart Monitoring solutions are helping workplaces worldwide protect their employees while maximising productivity. Get in touch with our product experts today to find out how our smart monitoring technology can improve your workplace and warehouse operations.